Industrial projects depend on predictable results, especially where repeat work or demanding tolerances are involved. A modern CNC plasma cutter removes much of the unpredictability tied to hand-guided tools and supports the accuracy needed for batch fabrication. This shift toward controlled cutting allows production teams to match designs, reduce rework, and protect margins on repeat orders.

Uniform Cut Paths That Stay Identical from the First Piece to the Last

A CNC plasma cutting machine follows programmed coordinates without drifting off course, which allows each part to match the previous one with remarkable consistency. Manual cutting, even in skilled hands, typically shows small variations from pass to pass.

Repeatability becomes especially important as order sizes grow. Uniform paths reduce the chance of mismatched joints or uneven material fit, making it easier for downstream processes to stay on schedule. CNC companies near me that work with tight-tolerance components depend heavily on this path accuracy to maintain dimensional integrity throughout an entire production run.

Consistent Torch Speed That Removes Human Variation in Every Pass

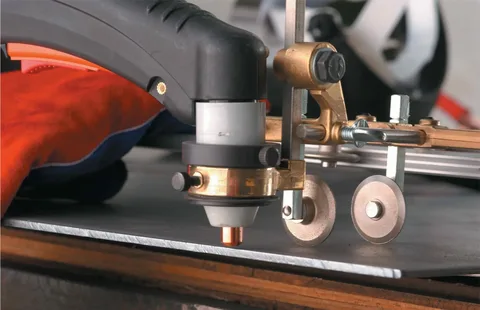

Speed control sets automated systems apart from hand cutting. A plasma cutter operated manually often slows or speeds up as the operator moves through a curve or heavier section.

In contrast, a CNC plasma cutter maintains a precise torch speed from start to finish. This steady movement supports cleaner kerfs, predictable melting behavior, and lower risk of overheating or undercutting. CNC machine shop near me facilities often rely on this consistency to keep parts aligned with inspection criteria and to reduce scrap rates across large batches.

Predictable Edge Quality That Holds Tight Tolerances on Repeat Jobs

Automated plasma systems generate edge finishes that stay consistent across hundreds of parts. Manual methods usually create varying bevels or roughness depending on angle, fatigue, or torch distance. A controlled torch path helps preserve the same edge geometry every time, minimizing the amount of post-processing required. This helps CNC services near me maintain schedule accuracy by streamlining everything that comes after cutting. Shops working with production-level metalwork often depend on these predictable edges to hold dimensions through machining or secondary operations.

Smooth Contour Reproduction That Manual Tools Can’t Match

Fine contours tend to expose the limitations of hand cutting. Tight curves, nested designs, or repeated cutouts easily drift when guided manually.

Automated plasma tables excel here because the machine follows digital geometry rather than operator judgment. This precision supports architectural components, brackets, and fabricated parts that require reliable contour accuracy across repeated jobs. CNC machining near me often pairs this stage with secondary milling, and smooth contours reduce the machining time required to finalize each profile.

Reliable Dimensional Control That Keeps Batches Perfectly Aligned

Dimensional control is one of the strongest advantages of CNC-based cutting. Manual cuts frequently widen or shift as the operator moves around the sheet, which can compound over a long run of identical parts.

Digital cutting systems avoid these incremental errors by referencing the same zero point throughout the batch. For manufacturers that rely on interchangeable assemblies, this alignment supports faster production and fewer adjustments during fit-up. CNC machine company operations producing equipment panels, structural frames, or repeated mounting patterns invest heavily in this level of control.

Steady Cut Depth That Avoids the Uneven Results of Hand-guided Methods

Cut depth affects everything from strength to cosmetic quality. Manual plasma cutting often dips too deep or not deep enough as hand motion changes.

CNC plasma cutting machine systems regulate arc height in real time, keeping the torch positioned where it produces the intended cut depth. This prevents thinning in critical areas and ensures the final part meets its load or structural requirements. Production teams count on steady depth to maintain reliable performance during final assembly or welding.

Repeat-ready Precision That Supports High-volume Fabrication

High-volume fabrication leaves little room for variation, and that is where CNC automation outperforms manual cutting by a wide margin. Repeat-ready accuracy reduces rework, limits scrap material, and helps each part fit seamlessly into larger assemblies.

This repeatability aligns directly with the needs of industries that operate under strict quality and output expectations. Amtec Solutions Group supports high-volume manufacturing through advanced CNC plasma cutting and machining systems designed for consistent, production-grade accuracy.