A well-built frame begins long before the first connector tightens into place. Assembly becomes smoother and more predictable when each step is handled with preparation, order, and the right understanding of how MiniTec Aluminum Framing works. Anyone using MiniTec extruded aluminum framing or other T slot extrusion systems quickly sees how small details shape the quality and accuracy of the finished structure.

Clear and Level a Flat Work Area

A flat, open workspace prevents alignment problems later. MiniTec Aluminum Framing depends on square joints and straight profiles, so uneven surfaces can cause twist or misalignment before the structure even stands upright. Removing clutter also makes it easier to keep track of connectors, brackets, and fasteners throughout the build. A level area supports cleaner measurements. Builders gain the ability to confirm that each profile sits flush before tightening hardware. With T slot aluminum extrusion systems, precision at the base becomes the foundation for accurate assembly throughout the project.

Unpack and Verify All Profiles and Hardware Components Against Your Project List

Verifying the parts list avoids unnecessary delays. MiniTec extruded aluminum framing comes in many lengths, series, and accessory options, making it important to confirm that every profile and fastener matches the intended design. A missing connector discovered early saves time and prevents rework later.

Inspecting items during unpacking also helps catch damage. Straight profiles and intact grooves ensure the T slot extrusion system assembles smoothly without forcing pieces together. Confirming everything upfront supports a predictable build from the start.

Organize Aluminum Profiles by Size and Series to Streamline the Build

Sorting profiles creates efficiency. With extruded aluminum T slot pieces arranged by size, the builder can grab the right components without constantly measuring. Series markings also matter because different accessories match specific profile families. Organized materials reduce assembly errors. Misplacing a shorter profile where a longer one belongs can throw an entire structure off square. Keeping T slot aluminum extrusion pieces clearly grouped supports a cleaner workflow and fewer corrections.

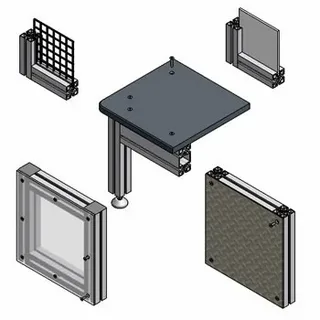

Construct the Bottom Frame Units First to Create a Stable Foundation

The bottom frame sets the tone for the entire build. By assembling it first, builders create a stable base that supports vertical profiles and accessories. MiniTec Aluminum Framing relies on accurate foundational geometry to ensure all upper components fit as intended.

A solid bottom frame prevents twisting and shifting during later stages. As the structure grows taller or more complex, the foundation carries the weight and alignment of the full system. T slot extrusion systems benefit greatly from this early stability.

Drive the Self-tapping Connector Screw into the Central Hole of the Profile End

Self-tapping connector screws form the core of many MiniTec assembly joints. Driving the screw into the central profile hole creates a secure anchor point that locks into internal channels. This step must be done with steady pressure to maintain thread accuracy. Once the screw seats correctly, it becomes the gripping point for connecting elements. A cleanly tapped screw ensures consistent holding strength throughout the T slot extrusion system and prevents premature loosening during operation.

Slide the Connecting Element into the T-slot of the Mating Profile and Align As Needed

Sliding connection elements into the T slot creates a tight mechanical link between profiles. Proper alignment ensures that the attached components sit square and follow the design layout exactly as planned. Builders should adjust the joint before tightening to avoid unnecessary strain.

Alignment influences long-term stability. With MiniTec extruded aluminum framing, misalignment can propagate upward through the structure, affecting accessories or motion components. A few extra seconds spent perfecting the fit improves the precision of the entire assembly.

Insert Any Required Square or Rhombus Nuts into the Grooves for Accessories or Panels

Accessory nuts allow attachments to mount securely anywhere along the profile’s groove. Square and rhombus nuts slide easily into the MiniTec Aluminum Framing system, preparing the structure for panels, guards, shelves, or motion hardware. Placing these nuts early prevents disassembly later.

Proper nut placement ensures smooth integration with additional components. Many builders stage nuts along the groove before attaching accessories so adjustments remain flexible. T slot extrusion systems excel at modularity, and these nuts are the key to that adaptability.

Tighten All Screws and Connectors with a Hex Key and Perform a Final Alignment Check

Final tightening locks the structure into its intended shape. A hex key ensures torque is distributed evenly across connectors, reducing the chance of warping or misalignment. Builders should tighten gradually, working across the structure to maintain uniform pressure.

A final alignment check confirms everything sits square and true. Straight edges, levels, and measuring tools help verify the geometry before adding panels or equipment. Clean alignment enhances the strength and appearance of MiniTec extruded aluminum framing.

MiniTec Solutions supports builders by supplying high-quality extruded aluminum T slot systems, accessories, and guidance for assembling reliable structures. Their expertise helps customers select the right profiles, connectors, and hardware to create frames that perform with precision and durability across countless applications.